|

Detailinformationen |

|||

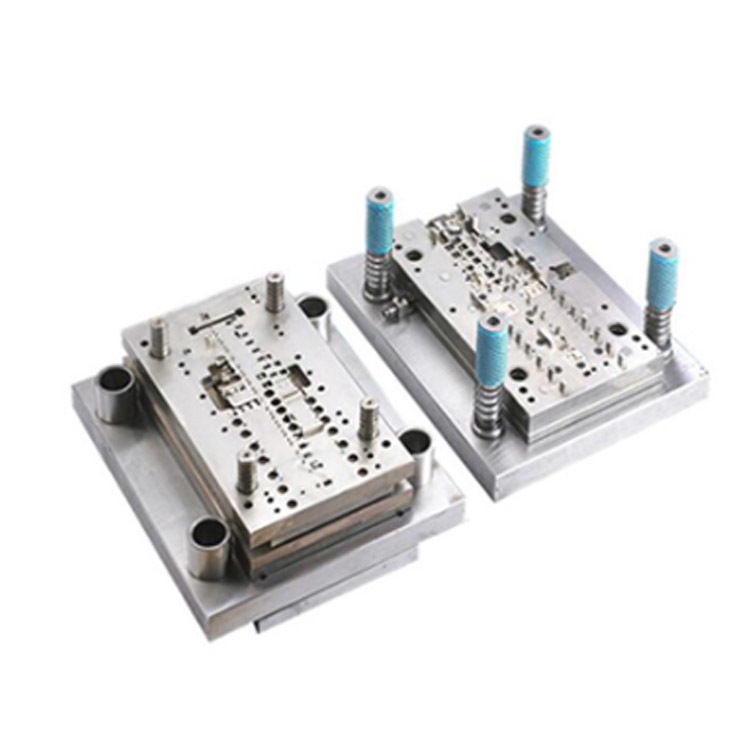

| Formungsmodus: | Stanzform | Produktmaterial: | Metall |

|---|---|---|---|

| Produkt: | Anschlussformen | Produktname: | Endkrempeln Schimmel |

| Benutzerdefinierte Verarbeitung: | Ja | Betriebsspannung: | 220 (V) |

| Schimmelmaterial: | Metall | Dringende Kraft: | 150 (KGs) |

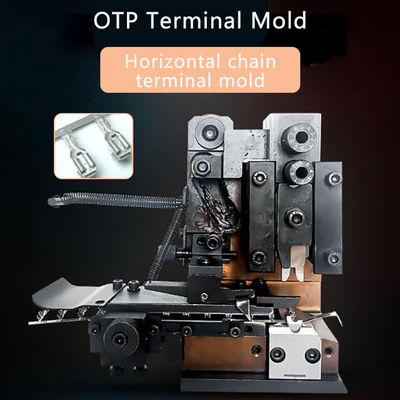

| Gewicht: | 4,5 (kg) | Spezifikationen: | OTP Single/ OTP Horizontal/ Straight/ U-förmig/ Flag-Form usw. |

| Anwendung: | Terminalmaschine | ||

| Hervorheben: | Hochgeschwindigkeitspressmaschine,Verschiedene Produkte Schleudern von Endverbindungsformen,Speichern Sie das Material |

||

Produkt-Beschreibung

Hersteller von verschiedenen Druckterminalformen für Kabel, Batterie, Pin-Kette, weibliche Lugs, Steckformen

Produktspezifikationen

| Produktbezeichnung | Schimmelschimmel |

|---|---|

| Typ | Verschiedene Terminaltypen |

| Gewohnheit | - Ja, das ist es. |

Wesentliche Merkmale

- Beste Preis für den Hersteller von Endform in China

- Für die Verarbeitung von mehr als 1 verschiedenen Produkten verwendet, weit verbreitet in der Mobil-, Werkzeug-, Rohstoff- usw. Industrie

- Arbeitet mit Hochgeschwindigkeitspressmaschine, Stanz SPM mehr als 200, Produktionszeiten 10 pro Tag

- Vermeidung von Abweichungen bei mehreren Maschinen und Pressen, die gleichzeitig arbeiten, indem allgemeine Maschinen und Pressen für die Produktion großer Mengen verwendet werden

- Bessere Gewährleistung der Produktqualität bei gleichzeitiger Verringerung der Anlagen- und Fabrikflächenanforderungen

- Einsparung von Material um mehr als 10%

- Verwendet Spulenmaterial und automatische Zuführung für die Produktion, was die Arbeitsintensität erheblich reduziert und die Arbeitskosten spart

- Verschiedene Modelle können nach Produktform, Größe, Musteranforderungen der Kunden entworfen werden

Produktbilder

Möchten Sie mehr über dieses Produkt erfahren?